مسكن

>

colours selection for stone crusher plant

مسكن

>

colours selection for stone crusher plant

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

colours selection for stone crusher plant

Crushing Plant Design and Layout Considerations 911

2016224 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences 2023228 Best Practices for Stone Crusher Plant Design: To ensure the success of a stone crusher plant, certain best practices should be followed during the design process. The following are some of the best Stone Crusher Plant Design: Best Practices for 202028 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone. The L18 orthogonal Aggregate Production Optimization in a Stone-Crushing Plant

get price

The Ultimate Guide to Designing an Efficient

2023223 Introduction. An aggregate crushing plant is a machine that processes a wide range of raw materials into high-quality aggregate, which is used in a variety of construction applications such as roads, buildings, 2016310 a) Maximum Feed Opening — 625MM (25 In.) b) Recommended Product Range — 100MM to 19MM (4 In. to ¾ In.) Short Head (Tertiary) Cone Crusher (Refer to Crushing Plant FlowsheetDesign-Layout 911 Metallurgist2016210 up. This stone addresses the critical design parameters that will increase the crushing capacity of the plant to 35 tonnes per hour. There are three main steps in Design of a crushing system that improves the crushing

get price

Stone crusher plant Henan Deya Machinery Co., Ltd.

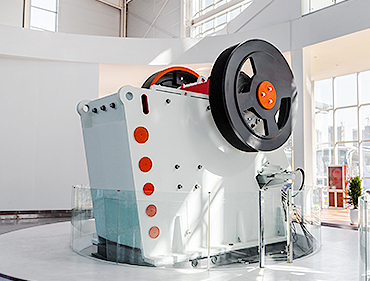

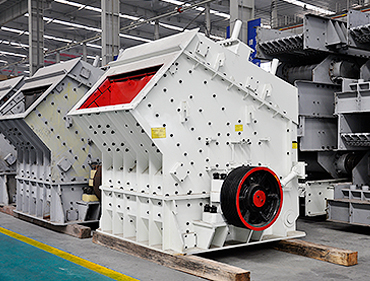

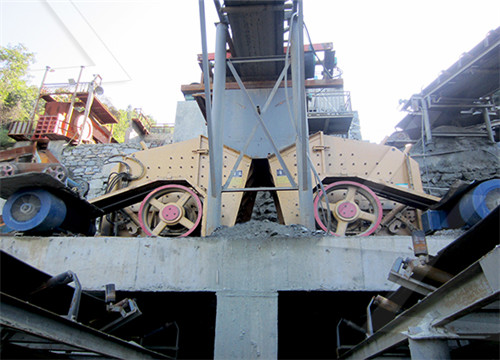

202275 2.1 Primary crushing stage. 2.1.1. Currently, there are three main types of primary stone crushers: jaw crushers, impact crushers and gyratory crushers. The impact The stone crusher plant consists of a crushing setup of excavators, feeders, primary and secondary crushers and screeners. They all work together to crush stone as efficiently as Stone Crusher Plant Setup Machinery Partnertypes of stone crusher machine pdf Mining. Feb 27,2013 grinding stone type pdf Coal processing system Machine for sale.Find the Right and the Top grinding stone type pdf for your coal handling plant!.various type of coal crushers machine type gypsum plaster in nigeria.?More detailedStone crushing plant BaichyWorking process of stone crusher fr/tye of crusher plants pdf.md at main hedaokuan/fr GitHub

get price

crusher selection for beneficiation plant Crushing and Screening Plant

Crusher equipment selection,Plant layout and design Mining Equipment. LOW VOLATILE COAL BENEFICIATION,design and colours selection for stone crusher plant Crusher Propel Industries is synonymous with advanced engineering, cost-effectiveness, innovative thinking and custom-made solutions. We are fast emerging as a most sought-after brand in the construction and mining sectors, both in Indian and international markets. We are the complete solution providers for mining and construction industries.India’s Fastest Growing Crushing Equipment Manufacturer2016712 An important point often overlooked by plant design and application people is that the crusher must have an adequate amount of evenly distributed feed. Figure 8 shows the effect of poor and good feed distribution. If the feed is correct, the crusher will have maximum produc- tivity (highest average crushing force) for minimum mechanical stress.Scientific Methods to Design Crushing and Screening

get price

7 Types of Stone Crusher and How to Choose the Best?

2021923 4. Sand Making Machine. The work of the impact sand making machine is continuous. It uses high-speed moving materials to strike iron, strike each other and friction between the materials to break. There are two crushing methods: "stone-on-rock" and "stone-on-iron".2022426 The soil was collected from disturbed sites (stone crusher plant) at different sites at varying depths, i.e., 0–10, 10–20 cm. The soil was collected in a polyethylene bag was marked according to the depth from different locations. The study sites’ soil showed diverse chemical variations among the four (east, west,Stone Crusher Dust and Its Impact: Accumulation Efficiency 2 According to Mr. Khoda, tracked plants have been registering a growth of 30-35% CAGR growth from the year 2005 onwards. Besides providing larger residual and salvage value, as compared to static plants the mobile plant has its advantage in terms of flexibility both in terms of installation and operation.Mobile vs. Static Crushers: The Better Deal NBM Media

get price

How does a stone crushing plant work? LinkedIn

Published Jan 3, 2023. + Follow. A stone crushing plant typically works by crushing large stones into smaller pieces. The crushed stones are then transported through a conveyor belt to a storage202275 2.1 Primary crushing stage. 2.1.1. Currently, there are three main types of primary stone crushers: jaw crushers, impact crushers and gyratory crushers. The impact crusher, as a primary crusher, is only suitable for medium to soft rocks, such as limestone, and thus its use is limited. Large jaw crushers with a maximum feed length of up to 1mStone crusher plant Henan Deya Machinery Co., Ltd.\n \n RISK ASSESSMENT M s.Shivsai Stone Crusher \n. Risk assessment is a systematic method of identifying and analyzing the No tree,loose stone or debris will be permitted to remain within 3 meters of the.METHOD STATEMENT Former Whitehall Park School,METHOD STATEMENT Former Whitehall Park School,Ashmount Road,London method statements and risk assessments of crusher plant

get price

Stone Crusher Plant Setup Machinery Partner

The stone crusher plant consists of a crushing setup of excavators, feeders, primary and secondary crushers and screeners. They all work together to crush stone as efficiently as possible. Conveyors connect everything, moving the crushed material from one station to the next. Stone crusher plant equipment is divided into two categories:In 1881, Philetus W. Gates received a U.S. patent for his device featuring the basic ideas of today’s gyratory crushers. In 1883 Mr. Blake challenged Mr. Gates to crush 9 cubic yards of stone in a contest to see which crusher would finish the job faster. The Gates crusher completed the task 40 minutes sooner!Types of Crushers: What You Need to Know Machinery The stone crusher plant is used for producing sand, rock and stone for construction, highway, railway and other applications. Fote Heavy Machinery, with 40 years of experience in the stone crushing production line, is skilled in the production line process design and has a high-cost performance.colors selection for stone crusher plant search results

get price

GitHub

Stone Crushing Plant Project Cost Stone Crushing Plant Project Cost; A STONE CRUSHING UNIT seiaacg.up an Stone Crushing unit at village Sargipal,Jagdalpur,Bastar,Chhattisgarh with the capacity of 36000 MT p.a.(with one shift of 8 hours for 300days) The Capacity of Pl cost of crusher stone in sa cifmancollege 201647 Compression crushers which squeeze the material until it breaks. Impact crushers which use the principle of rapid impact to shatter material. A ttrition crushers which use both impact and grinding to shear material. Jaw crushers, cone crushers, gyratory crushers and roll crushers all operate on the compression principle.Selecting the right type of crushing equipment Quarry

get price