مسكن

>

dust collector for quartz process plant

مسكن

>

dust collector for quartz process plant

منتج

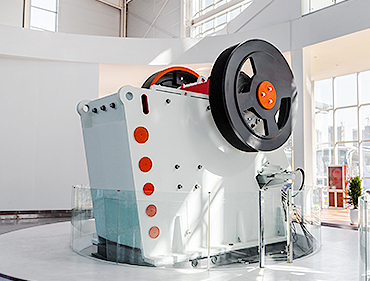

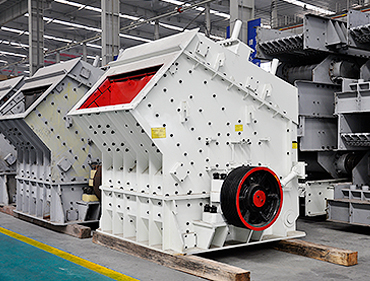

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

dust collector for quartz process plant

Dust Collector

Dust collectionGas absorption. 1.Dust collection design adopted LDM3-192 pulse bag dust collector set, it consists filtration chamber, filtration bag, dust hopper, flopping valve, 2020112 A well-designed dust collection system has multiple benefits resulting in a dust-free environment that increases productivity, (PDF) Design analysis of Dust collection system2023912 Dust Collection and Air Pollution Control: Dust Collectors: It's essential to have a dust collection system to capture airborne dust and prevent it from contaminating quartz stone powder manufacturing plant equipment

get price

Reducing Air Pollution in a Lime Plant with Conveyor

2022831 in order to maximize the negative pressure created below the dust collectors. The goal was to successfully transfer the negative pressure all the way down 202211 The Dust Collector plays a vital role in industrial process. The Machine is to be used in these industries, due to the spreading of hazardous dust to prevent diseases. Design and fabrication of cyclone dust collector for industrial202211 The Dust Collector plays a vital role in industrial process. The Machine is to be used in these industries, due to the spreading of hazardous dust to prevent diseases. Design and fabrication of cyclone dust collector for industrial

get price

quartz sand mill dust Capabuild

Ball Mill, Dust Collector in Quartz Sand Grinding Plant Jun 07, 2017 Ball Mill, Dust Collector in Quartz Sand Grinding Plant --- . Mills For Grinding Quartz hiaimpolymers. Ball mill for quartz sand grinding is provided by mpl,And it's widely used in many practical fields. mpl is a professional production Stone grinding2020416 CONTACT US. Having the proper dust collection equipment can help protect stone fabrication workers who may be inhaling dangerous amounts of silica dust while cutting, grinding and sanding pieces of “engineered stone” to make kitchen and bathroom countertops. Dust Collection Modules provide a safe, effective way for Dust Collection Equipment to Help Stone Fabricators Protect Workers201945 RecoDust is believed to be an efficient way of processing steel mill dusts to produce reusable secondary raw material resources. The rising costs of the steel production process and the increasing public RecoDust—An Efficient Way of Processing Steel

get price

Design and fabrication of cyclone dust collector for industrial

202211 The salient features of the cyclone are as under [5] 1) The shape is designed in such a way that most of the moving parts are inside the chamber. 2) The dust particles are settled down at the bottom of the tank by the cyclonic process. 3) The terminal velocity plays an important role in dust collection.202391 dust controls to protect workers against the dangers of silica exposure,4 studies and OSHA inspections indicate that exposure levels may not be adequately controlled in some stone countertop fabrication worksites in the U.S. 5 This Hazard Alert focuses on countertop industry worker exposures to airborne silica dust, including from Worker Exposure to Silica during Countertop 2023930 If the dust being processed represents an explosion hazard, we must select the appropriate safety devices. 8. Select the Air/Fabric ratio. It is important to get the right air to fabric ratio. The air to fabric ratio of a filter is the rate of airflow through each square foot of filter media.How to select a dust collector AQC Dust Collecting Systems

get price

(PDF) Design analysis of Dust collection system ResearchGate

2020112 A well-designed dust collection system has multiple benefits resulting in a dust-free environment that increases productivity, comply with emission regulations, and improve industry employee202255 The most efficient method of controlling dust generated in a crushing plant is the use of dust suppression systems within a methodology and understanding of your process, mechanical stressors, enclosures, weather conditions and operational context. First, you should always try to avoid/eliminate dust generating activities as much as How do you control dust in a crushing plant? HomeAn industrial dust collector captures the pollutants such as particulate matter, metal dust, buffing or grinding dust, polishing dust, superfinishing dust, rubber and various other types of dry dusts generated in the Industrial Dust Collector Machines and dust

get price

Quartz Sand Purification Treatment And

20231020 Physical properties of quartz sand. Quartz sand is quartz particles made by crushing and processing quartz stone. Quartz is a non-metallic mineral, a hard, wear-resistant and chemically stable silicate 2021226 2.2 Purification principle of wet scrubber. The principal mechanisms of for dust removal in a wet scrubber are inertial impaction, interception, and diffusion (Azzopardi et al. 1991; Goniva et al. 2009).Since wet scrubbers mainly rely on radial mixing impellers to complete the purification process, the role of the radial mixing impeller in this study’s Experimental study of the dust-removal performance of a 2023223 The separation of fine mineral particles, especially using environmentally friendly approaches, is one of the main problems in the processing of low-grade ores and the re-processing of mining tailings. This work assesses the potential of biosurfactants as collectors in the flotation of ultrafine (smaller than 20 μm) particles of hematite and Eco-Friendly Collectors for Flotation of Fine Hematite and

get price

Reducing Air Pollution in a Lime Plant with Conveyor

2022831 The traditional vertical dust collector option A second solution considered was a traditional vertical dust collector. This option would involve installation of a conventional centralized dust collector with filter bags and cages. However, proper duct routing was going to be difficult to achieve because of space requirements. Numerous 2021828 Abstract. This stone presents aspects of monitoring material dust emissions from stationary emission sources (monthly dust measurements performed on cement mill stacks—mill outlet and separator outlet). Additionally, the Portland cement mill technological process (its component parts), as well as the solutions regarding the Dust Emission Monitoring in Cement Plant Mills: A Case Dust Collectors. Another way that quartz shops control dust from quartz is by using machines such as collectors for construction dust particles. Using dry dust collectors, fab shops are able to filter the dust from quartz operations and, after it is clean, return the air back to the work environment.Quartz Dust Hazards Why Quartz Dust Is Hazardous Dangers of Quartz Dust

get price