مسكن

>

milling operations for ball mill pdf

مسكن

>

milling operations for ball mill pdf

منتج

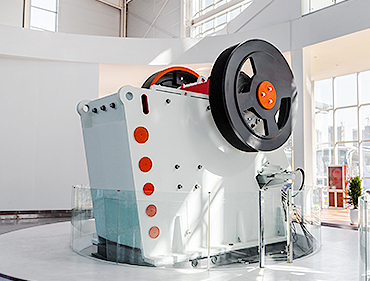

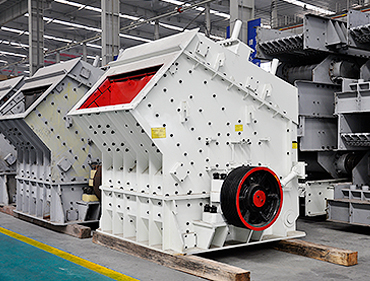

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

milling operations for ball mill pdf

Ball Milling in Organic Synthesis: Solutions and Challanges

201132 Type of reaction: The chemistry in ball mills is not restricted to a special type of chemical synthesis, if some requirements are fulfilled. At least one of the reactants and 2021219 The ball mill process parameters discussed in this study are ball to powder weight ratio, ball mill working capacity and ball mill speed. As Taguchi array, also known Comparative Study on Improving the Ball Mill Process For instance, a ball mill, which is a powder-processing technique involving deformation, cold welding, fracturing, and rewelding of powder particles, is used for mechanical alloying. Ball Mill an overview ScienceDirect Topics

get price

ResearchGate Find and share research

201261 ResearchGate Find and share research2021225 simulated the jar shape effect on efficiency of planetary ball mill [37, 387]. P.P. Chattopadhyay et al mathematically analyzed mechanics of planetary ball milling OPTIMIZATION OF MILLING PARAMETERS OF 2023828 Ball-milling Ball milling is an economic and facile technique to produce nanosized materials. It is a top-down approach of nanoparticle synthesis which includes Module-7 unit-3 NSNT Module 7 Ball-milling

get price

Modelling the performance of industrial ball mills using

198771 This ball mill modelling technique is illustrated using a case study on the design of a ball milling circuit for a particular grinding requirement and another case 2017115 Materials Science Ball Milling KONA Powder and Particle Journal CC BY 4.0 Authors: Luis Marcelo Tavares Federal University of Rio de Janeiro Abstract and Figures In the early 1990s the discrete...(PDF) A Review of Advanced Ball Mill Modelling20211028 processed. It’s also depending on the purpose of milling system and the capacity of the mill production. Due to different arrangement of mill in service, the fire ball position slightly will be different. The length of the PC pipe and the mill transportation factors such as air supply and distance will affect the combustion process. ThereforeAnalysis of the Coal Milling Operations to the Boiler

get price

What is Milling?- Definition, Process, and

20211018 Threads can be cut to a certain depth within the hole (bottom tap) or to the entire depth of a through hole. Milling is the process of machining using rotating cutters to remove material by advancing a where d b.max is the maximum size of feed (mm); σ is compression strength (MPa); E is modulus of elasticity (MPa); ρb is density of material of balls (kg/m 3); D is inner diameter of the mill body (m).. Generally, a maximum allowed ball size is situated in the range from D /18 to D/24.. The degree of filling the mill with balls also influences productivity of the mill Ball Mill an overview ScienceDirect Topics2020216 In drilling four holes and milling operation codes used are as follows. G91—Incremental command, G21—Metric units of input, G28—Machine zero return, G81—Repeat function-Fixed drilling cycle, G80—Fixed cycle cancel, G00—Point to point positioning mode of control, G01—Linear interpolation mode of control, M06—Tool change.Drilling and Milling Operation SpringerLink

get price

Milling ScienceDirect

201111 Milling of free form surfaces using ball-end milling is the main operation in this application, known as sculptured surface milling (SSM) (Choi and Jerard, 1999). Ball-end milling is also known as copying milling because of the old practice of copy forms from jigs 40 years ago before the introduction of CNCs in milling machines.2020311 Define the instantaneous tool position unit feed vector as v (t) at time t in MCS, so. 2.2. The Definition of MCS. Define MCS as O W-X W Y W Z W, corresponding unit axis vector as i W, j W, and k W.The instantaneous milling coordinate system (IMCS) and instantaneous tool coordinate system (ITCS) are established to describe the contact A Prediction Model of Cutting Force about Ball End Milling 2021715 The feed per tooth was selected based in the tools' provider recommendation for commercial TiAlN coated tools and for finishing operations, both with end-mill and ball-nose tools. The depth of cut selected was compatible with finishing operations in the milling process.Study of the wear behaviour of TiAlSiN and TiAlN PVD

get price

OPTIMIZATION OF MILLING PARAMETERS OF

2021225 simulated the jar shape effect on efficiency of planetary ball mill [37, 387]. P.P. Chattopadhyay et al mathematically analyzed mechanics of planetary ball milling [39, 40]. Y.T. Feng et al simulated the dynamics of planetary ball milling using DEM [41]. A. Yazdani et al estimated temperature, energy and particle size in planetary ball mill [422023627 2.2. Selecting Ball Mill Media. The choice of milling media (balls and jars) is a critical factor in the ball milling process, impacting both the milling energy and the final product size. Because of the wear and tear effect of the milling balls on the milling jar walls, it is crucial to use the right materials for the milling media . SeveralProducing Metal Powder from Machining Chips Using Ball Milling 200031 This stone presents an improved mechanistic cutting force model for the ball-end milling process. The objective is to accurately model the cutting forces for nonhorizontal and cross-feed cutter movements in 3D finishing ball-end milling. Main features of the model include: (1) a robust cut geometry identification method to establish A Mechanistic Cutting Force Model for 3D Ball-end Milling

get price

Machine learning-based instantaneous cutting force model

2019125 Zuperl and Cus ( 2004) developed a multilevel perceptron based NN models for prediction of cutting forces during the ball-end milling operation. The study compared the prediction capabilities of different NN architectures in the context of speed of processing, memory usage, robustness, etc. Quintana et al. ( 2011) developed an 2011531 The cutting tool used in milling operation is called milling cutter, which consists of multiple edges called teeth. The machine tool that performs the milling operations by producing required relative motion between workpiece and tool is called milling machine. It provides the required relative motion under very controlled conditions. TheseUNIT 1 MILLING Milling Indira Gandhi National Open 2018711 MILLING OPERATIONS Milling is the process of machining flat, curved, orMilling machines are basically classified as vertical or irregular surfaces by feeding the workpiece against a rotating horizontal. These machines are also classified as knee-type, cutter containing a number of cutting edges. The milling ram-type, manufacturing or bed MILLING OPERATIONS TYPES OF MILLING MACHINES

get price

Ball milling: a green technology for the preparation and

The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials.18 Being an groups depending on their operation mode: direct and indirect milling. In the rst case rollers or mechanical sha s directly act on the particles and transfer the kinetic energy. In the second

get price