مسكن

>

sand manufacturing method australia

مسكن

>

sand manufacturing method australia

منتج

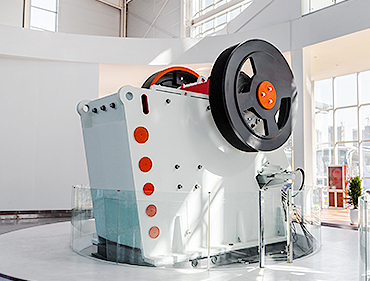

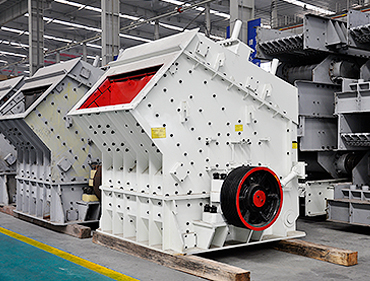

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

sand manufacturing method australia

Best river sand mining practices vis-a-vis alternative sand

202211 Importing huge quantities of sand is transforming the landscapes and lifescape of developing countries. Most of the sand is imported from Australia. 4. Best river sand mining practices. The following section describes best river sand mining practices 202021 The Murray Basin in southeastern Australia is proving to be a major mineral sand province that eventually will replace Australia’s (PDF) Technological developments in processing 2023228 Ore-sand is a type of manufactured sand resulting from the mining and processing of ores; its co-production implies the optimisation of these processes and the addition of processing stages to achieve the Ore-sand: A circular economy solution to reduce

get price

Production of Manufactured Sand SpringerLink

2022104 The method is as follows: primary treatment, the sewage for cleaning the finished ore is separated by a spiral sand washing machine to separate larger-grained 2019524 sand. Its purpose is to provide guidance on desirable source rock quality and production processes a quarry must have to make a consistent manufactured sand Guideline: Quarry assessment of “manufactured sand” Completion methods for weak formation. Nobuo Morita, in Geomechanics of Sand Production and Sand Control, 2022. Abstract. Sand production risks during formation Sand Production an overview ScienceDirect Topics

get price

Mechanics of Oil Well Sand Production SpringerLink

202361 Sand production is a common problem in the development of oil and gas fields. A large amount of sand production will lead to formation plugging, production 2023117 Prediction of sand production is by considering the erosion process of coupling finite element method, by simulating the fluid flow phenomenon, to observe the sand erosion process, and then to predict Frontiers Research advance of numerical 20191024 Manufacturing of mill roller has been done based on the design consideration of roller material and casting allowances. The design specifications of mill roller are given as net weight of 8106.1 kg with the final dimensions of outer diameter Ø980 mm, inner diameter of Ø500 mm, and 1800 mm height respectively.Design and analysis of sand casting process of mill roller

get price

Traditional Casting Process: Sand Casting

2022721 Include the pattern and sand into the pouring system. Remove the stencil. Filling the cavity with molten metal, preparation, and melting the metal material. Pour the liquid metal and wait for the metal to 202332 To promote the green and sustainable development of the foundry industry, it is necessary to further explore the new method, new technology, and new equipment for green foundry. In this , an innovative green casting method is proposed. The digital frozen sand casting technology uses water as the binder to replace the organic/inorganic Research on Green Casting Technology and Equipment of2012121 2. Lusty A. Sand industry leads revival of Japanese aggregates. In: Quarry 16(10), October 2008; 90-92. 3. Cement Concrete Aggregates Australia. Manufactured sand national test methods and specification values. Research report, 2007; 17-18. 4. Lusty A, Pilegis M. Sand manufacturing from quarry surplus.Manufacturing sand for a low carbon era Quarry

get price

KRB1 sand for cats and cats sand manufacturing method

The present invention provides a simple and easy treatment of feces, such as urine and urine generated in breeding cats for , as well as functionality such as odor deodorization, antibacterial, anion, and far-infrared light caused by feces and urine. It relates to a pet sand and a manufacturing method for producing the same. In the present invention, a main 201226 PURPOSE: Sand for pet cats and a manufacturing method thereof are provided to minimize dust generated in the use of sand for pet cats, to prevent various diseases induced by the dust, and to offer pleasant surrounding environment. CONSTITUTION: Sand for pet cats comprises a main material composed of zeolite in the Sand for cats and cats sand manufacturing method Google 202361 There is a difference between capillary force and cohesive between particles. From field practice, for example, in the North Sea oil field, a well drilled in 1981 started with a reservoir pressure of 44.13 MPa and a production rate of 795 m 3 /d, and after the supplemental perforation the production rate reached 1908 m 3 /d, and even at such Mechanics of Oil Well Sand Production SpringerLink

get price

Resource, characteristic, purification and application of

2022615 Quartz crystals are oxide minerals with the trigonal or hexagonal system, whose cell parameters are: a = 4.916 Å, b = 4.916 Å, c = 5.405 Å. The Si-O bond angle in α-quartz is 144° and the bond length is between 0.16101 and 0.16145 nm (Götze, 2009). The different types of quartz crystals are shown in Table 1.2018616 manufacturing and conventional process Nishant Hawaldar1Jing Zhang1 Received: 5 January 2018/Accepted: 10 March 2018/Published online: 19 April 2018 Making this core by conventional method requires around 7.7 kg of sand, but on the other hand, the 3D printed core which was made in single piece required 4.4 kg. The sandA comparative study of fabrication of sand casting mold 201911 The method uses a sand casting process with variations in pouring temperature and is tested by an impact test. The purpose of this study was to obtain good impact strength properties which areProcess knowledge for improving quality in sand

get price

A review on additive manufacturing of sand molds by

20181010 Although multiple methods of additive manufacturing may be used to create sand molds [5], binder jetting seems to remain the most popular process. Designing and producing patterns for traditional2020420 Traditional manufacturing sand casting process. Sand casting is a method of producing castings by sand mold, which is made of sand, binder and other auxiliary materials. The processes of sand casting include modeling, core making, box closing, pouring, sand falling, cleaning, inspecting, recycling, etc.Low carbon, high efficiency and sustainable production2022107 The diminishing natural sand has facilitated the booming of the sand manufacturing industry, and intelligent management of sand factories, in a time- and cost-efficient way, has become a growing tendency for the future. A role has been played in achieving intelligent management by constructing a smart supply chain. However, the Construction of a Smart Supply Chain for Sand Factory Using

get price

The Hidden Environmental Toll of Mining the World’s Sand

201925 But sand also makes up 90 percent of asphalt on roads. It also is used for land reclamation in places like Singapore. And it is widely used in industries such as glass manufacturing and fracking, where it forms part of the gritty mixture injected underground to fracture shale deposits and release natural gas or oil.2017101 These include Selective Laser Sintering, Laminated Object Manufacturing, Fused Deposition Modelling, Stereo lithography and especially, the 3D printing (3DP) process to produce sand cores, patterns, shells and entire mould assemblies for sand casting applications. The interest in rapid casting using AM has increased with the 3D printing for rapid sand casting—A review ScienceDirect

get price