مسكن

>

dry magnetic separator australia

مسكن

>

dry magnetic separator australia

منتج

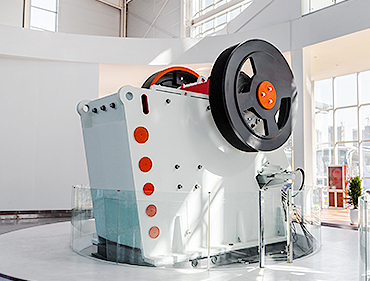

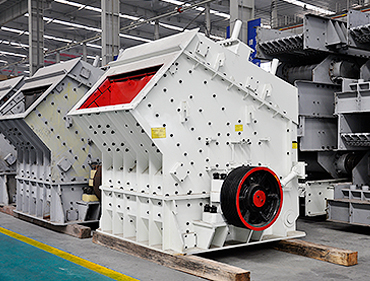

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

dry magnetic separator australia

Eriez Dry High Intensity Magnet

Eriez Dry High Intensity Rare Earth Roll Magnetic Separator. With the ever increasing demand for high-purity feedstocks used in manufacturing, Eriez offers its Dry High Eriez is world authority in magnetic separation technologies. Since 1942, Eriez provides a range of permanent and electromagnetic separators for many industries.Eriez Magnetic SeparationThe laboratory induced roll is capable of a varying magnetic field from low to high magnetic intensities. At high coil amperage the roll can induce up to 20,000 gauss field strength Laboratory Magnetic Roll Extraction Equipment MARC Tech

get price

Assessing the performance of a novel pneumatic magnetic separator for

202091 A novel low-intensity pneumatic planar magnetic separator designed to recover and concentrate fine-grained magnetite minerals is investigated and the 2021624 Magnetic Separators CPG Resources Mineral Technologies Leaders in Mineral Separation Expertise. Experience. Superior Technology. The Reading range of MT Brochure READING V2 AusIMM2022930 PDF Dry permanent magnetic separators have been widely used in the mineral and coal processing industries due to their simple operation and high Find, read and cite all the research...(PDF) Dry Permanent Magnetic Separator: Present

get price

Dry Permanent Magnetic Separator: Present Status and

20231023 Dry magnetic separation is a technology that sorts magnetic minerals from gangue using air as the medium instead of water. When raw ore is fed to the 2020827 Elder, J.; Sherrell, I. Dry versus wet magnetic separation—Horses for courses. In Proceedings of the 8th International Heavy Minerals Conference, Perth, Minerals Free Full-Text A Novel Pneumatic Planar Magnetic Separator202321 The low-intensity dry magnetic separator (LIDMS) discussed in this study is mainly used to recover ferromagnetic materials under dry conditions. However, the efficiency of traditional LIDMS for separating fine materials is not satisfactory due to the poor dispersion and fluidity in the air [11]. The electrostatic force and Van Der Waals forceSeparating efficiency of ferromagnetic particles and

get price

Assessing the performance of a novel pneumatic magnetic separator for

202091 Kelsey et al. (2017) used the Cyclomag-100 dry magnetic separator to recover and concentrate a finely ground (~100 The Australian Government Research Training Program Scholarship and the Future Industries Institute of the University of South Australia are thankfully acknowledged for the financial support toward the Ph.D. studies 2022930 Structure diagram of CTG permanent magnet double-barrel dry magnetic separator: 1-electric vibration feeder; 2-stepless governor; 3-electric motor; 4-upper roller; 5, 7-circular magnetic(PDF) Dry Permanent Magnetic Separator: Present StatusThe Powder Transfer Magnet is a high-intensity, sanitary design magnetic separator, engineered specifically for sensitive powder applications such as in dairy, nutraceutical, and pharmaceutical plants. This separator features high-intensity Acutex ™ Probe Magnets configured to remove even the smallest and weakly-magnetic fragments (includingPowder Transfer Magnet Dry Magnetic Separation

get price

Chapter 2 Magnetic Separation Springer

2023321 Fig. 2.2 Classification of magnetic separators from different perspectives [14]. Re-drawn figure Dry low-intensity magnetic separators (DLIMS) are generally employed to: upgrade iron ores containing relatively large particles and strongly magnetic minerals separate iron pieces from steel mill slags and blast furnacesDry high intensity magnetic separators LSV. The high gradient magnetic separator LSV equipped with an extra strong magnetic roll, is a scaled-down (but fully operational) version of the high intensity magnetic separator VMSV. It is used for a continuous and automatic separation also of very small (even c.30 µm) and weakly magnetic particles (e.g. Dry high intensity magnetic separators LSV SOLLAU200031 Magnetic separation is a versatile technique widely used in the mining industry. Drum-type wet low-intensity magnetic separation (WLIMS) represents the backbone of the iron ore upgrading circuits since the mid 19 th century. However, it has been traditionally applied through guidelines that commonly disregard the ore properties The mechanism of magnetics capture in the wet drum magnetic separator

get price

Iron Separator, Magnetic Stirrer, Magnetic Separator Huate

20231016 We are specializing in manufacturing superconducting magnet, cryogenic superconducting magnetic separation equipment, magnetic iron separator, magnetic separator, magnetic stirrer, ultra-fine grinding and classifying equipment, mining compete set equipment, medical magnetic resonance imaging (MRI) etc.201533 High intensity dry magnetic separators are gaining popularity for the separation of para-magnetic minerals due to the cost economic factor. Induced roll magnetic separator is found to be an effective dry separator for the separation of fine particles. Separation efficiency of this separator depends on mineral characteristics and the design Prediction of Separation Performance of Dry High Intensity MagneticThe Reading Rare Earth Magnetic Drum (RED) uses a unique 5 pole magnetic element to generate a field intensity in excess of 0.7 Tesla on the drum skin. The magnetic element design affords the maximum field gradient and the 5 poles enables additional cleaning of the magnetic stream. This gives a very selective separation at high throughputs compared to Magnetic separation equipment Reading range Mineral

get price

Full article: Demonstration of dry magnetic separation to

A Reading dry induced roll magnetic separator (IRMS) was utilised for this purpose. This device is designed for the highly selective dry magnetic separation of samples of granular materials during laboratory use or test work. Particles are separated according to the magnetic susceptibility and the provision of a continuous variable roll speed20231023 Minerals 2022, 12, 1251 4 of 20 Figure 1. Schematic diagram of CT series magnetic pulley structure. 1—multipole magnetic system; 2—cylinder; 3—magnetic conductor; 4—belt [8].Dry Permanent Magnetic Separator: Present Status and 202275 The magnetic separator plays a role in improving the grade of ore, purifying solid and liquid materials, and recycling waste. With the application and development of magnetic separation technology, magnetic separation equipment is constantly updating and replacing, and dry magnetic separation has experienced remarkable technological Dry Magnetic Separation Innovations RecyclingInside

get price

Separating efficiency of ferromagnetic particles and

202321 Introducing airflow into the low-intensity dry magnetic separator (LIDMS) is an effective means to improve the separating efficiency of ferromagnetic particles under dry conditions. In this study, a multi-physical coupling model was established to compare the separating performance of LIDMS under four typical air supply modes. The result showsMultotec magnetic separators: Recover up to 99.99% in DMS applications. Recover fine particles down to 15 microns. Flexible magnetic recovery options for wetdry slurries. Incorporate oil-cooled electromagnets that increase efficiency. Are manufactured in overbelt widths that meet all standardinternational sizes up to 2 400 mm for trampMagnetic Separators Multotec

get price