مسكن

>

operating cost for cement grinding unit

مسكن

>

operating cost for cement grinding unit

منتج

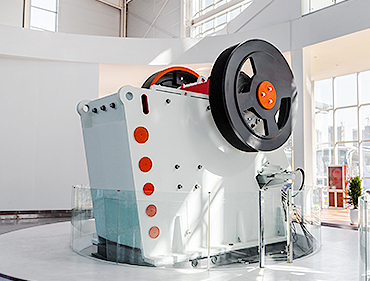

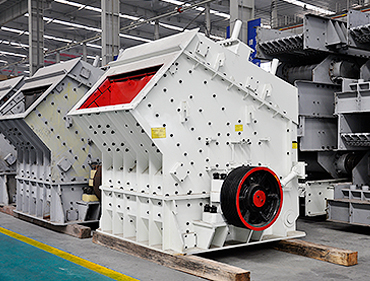

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

operating cost for cement grinding unit

Grinding process optimization — Featuring case studies and operating

2017619 Abstract: As a world-wide leader in grinding solutions for the cement industry and understanding the changing needs of cement producers and how to tailor 20191011 The cement grinding plant is an individual section of finished cement production. How much do you know the cement grinding unit? AGICO Cement is a Cement Grinding Plant Overview Cement Grinding Unit AGICO Cement1. Introduction The Cement Industry is under increasing pressure to become more profitable. Globally, there is overcapacity of production. To be competitive, Production Units need to Optimizing Operating Costs to Improve Profitability in a Cement

get price

Energy-Efficient Technologies in Cement Grinding

2016105 In this chapter an introduction of widely applied energy-efficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over What are the infrastructure costs for setting up a cement manufacturing plant? What are the capital costs for setting up a cement manufacturing plant? What are the operating costs Cement Manufacturing Plant Project Report Setup and Cost 202353 For the 20 cement plants expected to be in operation by 2020, the cost-effective energy saving potentials is 159 GWh for electricity and 7.2 PJ for fuel, reducing A comprehensive investigation of a grinding unit to reduce

get price

Cement grinding optimisation ScienceDirect

2004111 In the oil and gas industry, CC has been widely utilized, in the context of gas purification, being an essential gas processing unit, with CC capacities up to 1.4 Mt 2014619 The study evaluates the energy consumption of both wet and dry processes cement manufacturing plant in Nigeria. Enrgy consumption data collected for the period 2003 to 2011 were used to Energy and Cost Analysis of Cement Production 2021826 of bags and bulks cement product from cement plant until customers that has minimizing supply chain costs. As for the potential reduction in supply chain costs, it can save up to Rp49.6 Billion if existing allocation compared to optimal allocation and also recommendation to stop operation of packing plant due to low production utility. KeywordsProduction and Distribution Model in Cement Industry

get price

Review on vertical roller mill in cement industryits

202111 India is the world's second largest producer of cement and produces more than 8 per cent of global capacity. Due to the rapidly growing demand in various sectors such as defense, housing, commercial and industrial construction, government initiative such as smart citiesPMAY, cement production in India is expected to touch 550–600 million Global cement producer Votorantim Cimentos achieves multi-site digitalization with ABB industry-specific solutions. 2022-04-05. ABB upgrades process control systems and cement grinding units in UAE for increased uptime and uniformity across multiple sites. 2021-02-01. ABB digital control systems to modernize major cement plant in Oman. 2020-10-29.Cement industry solutions ABBHowever, the unit cost for wear parts for a ball mill is much lower than for a vertical roller mill. For a ball mill grinding OPC to a fineness of 3200 to 3600 cm2/g (Blaine) the cost of wear parts (ball, liners and mill internals) is typically 0.15-0.20 EUR per ton of cement.Cement grinding Vertical roller mills VS ball mills

get price

Grinding Solutions Indian Cement Review

2015131 From hub-and-spoke model to split grinding; from single-grinding solution to a combination of system solutions; and from energy-intensive traditional ball mill to upgraded versions and use of pre-grinders, the cement industry is shifting towards more energy-efficient grinding solutions. ICR trains its spotlight on the current technology 2017619 Abstract: As a world-wide leader in grinding solutions for the cement industry and understanding the changing needs of cement producers and how to tailor solutions to meet those needs. Optimizing output, improving efficiency, and reducing CO2 emissions while keeping investment costs to a minimum are common challenges that the Grinding process optimization — Featuring case studies and operating2022531 • Freight cost: Transportation of cement over long distances is expensive, and freight cost which accounts for about 20%-25% of the operating cost are among the largest expenses for a cement company. The average market radius (lead distance) to which the company caters is analysed. Cement can be transported through rail, road or sea Rating Methodology Cement Credit Rating

get price

Latest trends in modular cement grinding plants Cement

For investors, beside investment and operating costs, there are a number of reasons to further evaluate the idea of setting up a modular cement grinding plant. The main reasons are: Short time to market, quick return of investment. Simple installation and commissioning, pre-assembled solution. New market entry, allowing access to local and2 JK Lakshmi Cement, a part of JK Organisation, witnessed a notable 6.77% surge in its stock price, hitting a four-month high of ₹ 719.90 per share during Friday's early trading session, propelledJK Lakshmi Cement shares zoom 6.7% as net profit grows This grinding unit produced only PPC cement with a capacity utilization of 112.96%. Electricity consumption is estimated to be 108.87 M kW h. Plant P7: Combined cement production is 1.36 Mt with 86.33% capacity utilization. The main production is PPC cement (94%). A significant amount of electricity is supplied to the grid.Clinkerization Process an overview ScienceDirect Topics

get price

300 ton grinding unit cement plant cost -china

300~5000 ton per day small cement plant with compact structure. 300~5000 ton per day cement clinker grinding plant. FOB Price: US $80000 100000 / Unit.201751 Therefore, optimizing grinding operation, improving grinding process efficiency and reducing grinding cost are of great significance for the mineral resources processing industry to reduce its(PDF) Grinding process optimization — Featuring case 2020514 According to the data we know, the total cost of a cement plant is estimated to be US$ 17,000 to US$ 20,000 per ton. One thing to be clear, this is just an estimation, in the real cement plant building, the cement factory cost is affected by various factors, including the significant difference in the cost of land, availability of limestoneHow Much Does It Cost To Start A Cement Plant?

get price

Cement Grinding Cement Plant Optimization

Highly energy intensive unit operation of size reduction in cement industry is intended to provide a homogeneous and super fine (3000-4000 Blain) cement. Grinding operation is monitored for following parameters to ensure objectivity and economy of operation. Grinding Operation Objectives and KPIs. Chemical analysis of cement, generally on

get price